The classic brick that we all know is made by firing clay blocks at high temperatures. Our bricks, on the other hand, are cold-pressed from crushed stone of a precise fraction, specifically limestone. The brick itself is made by pressing this mixture of crushed stone into a precise form. Thanks to this, the brick can boast high homogeneity and bulk density, which are properties that determine key technical parameters: load-bearing capacity and water absorption. Water absorption is important for frost resistance, i.e. for the life of the brick.

While ordinary clay bricks need to be protected with additional layers of plaster against weathering, pressed limestone bricks do not need any additional protection.

In addition, thanks to the production process, which is extremely energy-efficient compared to fired bricks, the Mořina brick is very environmentally friendly and has an almost zero carbon footprint. In financial terms, this means that a significantly more expensive and higher-quality input raw material can be offset by a cheap production process, making a stone brick comparable in price to a regular clay brick.

It doesn't have to be grouted or plastered!

Thanks to the high compaction of the material during production, our brick achieves exceptional strength, allowing you to build a more subtle wall and thus save valuable space.

Thanks to its composition of natural aggregates, the brick has very low water absorption, making it very suitable for outdoor use. Its properties correspond to the much more expensive sintered bricks known as clinker.

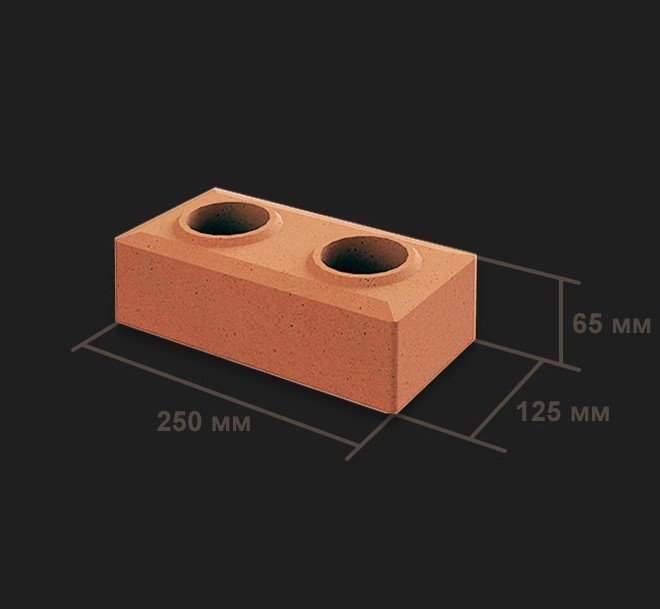

The bricks are made in precise stainless steel molds with two circular holes with locks that always hold the bricks together in the optimal position, so the result is a perfectly straight wall without unwanted joints in every case. The bricks do not need to be jointed. Ideal for self-construction.

Circular holes in the bricks can be used to route water, waste, electrical cables and heating pipes during construction. This eliminates the need for lengthy cutting into walls and subsequent filling of holes.

The energy-efficient production process (the brick does not need to be fired) guarantees a low carbon footprint for each brick and significant financial savings.

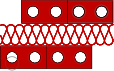

The biggest advantage of our bricks is the possibility of building a double perimeter wall with a gap. This is then filled with a suitable insulator, for example, expanded clay or blown polystyrene, which means up to 70% savings on insulator. Given that a 125mm wide wall is already load-bearing, the total thickness of the perimeter wall does not have to exceed 375mm and, in addition, you get a robust facade that is not easily compromised by anything.